Alfa Meccanica

Activity description

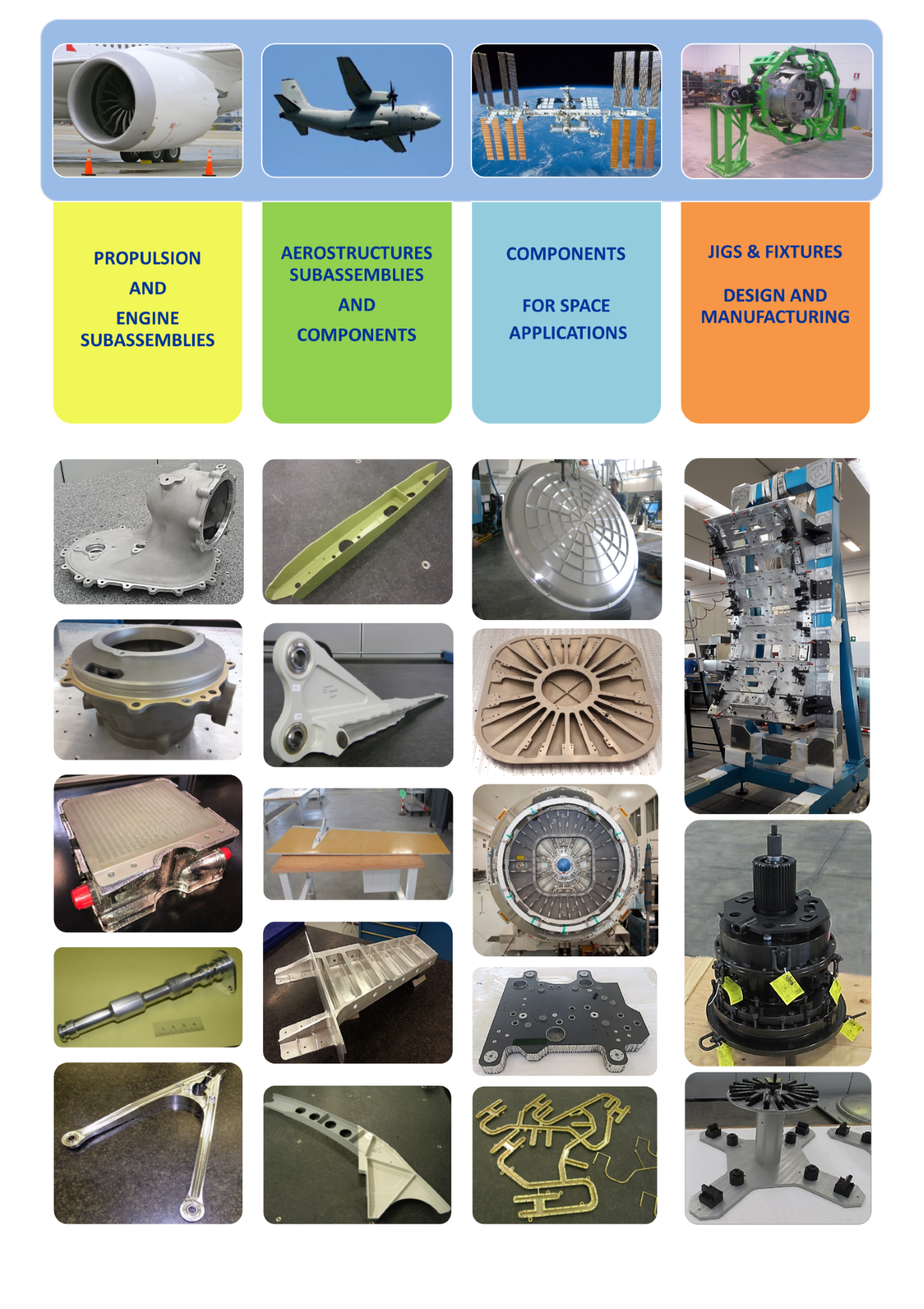

Active in Aerospace since 1975 Alfa Meccanica id specialized in high precision machining (NC multi-axis turning and 3-4-5 axis NC milling up to 8 m), EDM (die sinking, wire cutting and micro boring), installation of bearings/bushes, assembly of complex parts, FPI (NADCAP Certified), precision cleaning and cleanliness inspection (qualified by GE Aviation, according to P4TF21 specification), design and manufacturing of fixtures and jigs.

The following further activities are performed in-house: TIG welding, assembly, rotating components balancing operations and functional tests of some critical components, hydraulic testing of oil nozzles.

Moreover, Alfa Meccanica manages a network of certified suppliers to perform heat treatments, brazing operations, non-destructive controls, surface treatments, painting, and laboratory tests. For some space applications, ALFA MECCANICA has developed the trimming and drilling operations of honeycomb panels (with carbon fiber skins or aluminum skins) and the manufacture of waveguides with very high precision features. Alfa Meccanica is accustomed to working all the special materials used in aerospace applications from Aluminum to Nickel and Titanium alloys, from special steels to stainless steel.

ALFA MECCANICA is used to support R&D Projects, financed by the EU, in partnership with the Local Technological Excellences and Universities.

ALFA MECCANICA mainly operates in the aerospace and smart manufacturing fields.

Products

Aircraft Systems / Structure / Metal components / Sub Assy / Propulsion Systems / Rotating Components / Stationary Components / Accessories / Sub Assy

Space Systems / Platform / Structures and Mechanisms / Entry Descent and Landing / Ground Facilities and GSE's

Processes

Design / Modelling & Simulation / Drafting

Manufacturing / Machining / Milling / Turning / Cutting / EDM/ECM / Forming / Add. Manuf. / Special processes / NDT

Miscellaneous / Assembly & Test / Services

Other key sectors

Mechatronics