ROTOMORS

Activity description

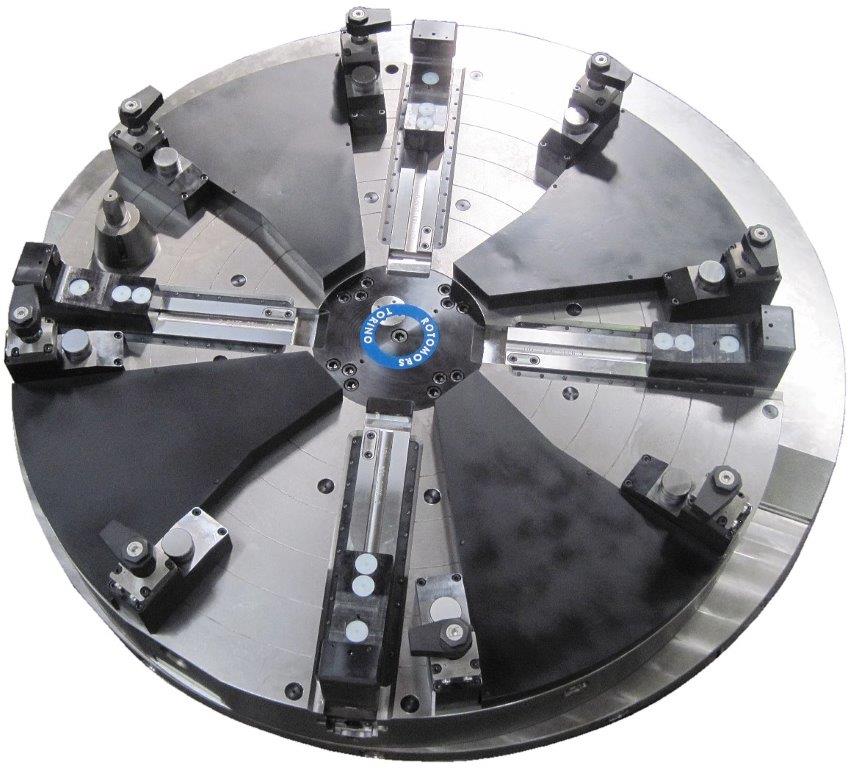

Clamping during a machining operation is a serious problem, which often makes the difference between the manufacturing of a component in cheap and convenient way or, on the contrary, the risk of damaging implementation costs and times.

No matter whether they are small or big, sturdy or fragile pieces, single or volume-manufacturing batches, to be machined on a modern machine tool it is necessary that the piece keeps its geometrical characteristics unchanged, without risks for operators and machines and, last but not least, it can be finished within the scheduled times and at the agreed cost.

For over 50 years, ROTOMORS at Grugliasco (TO) has been source of ideas and projects, which over the years have turned into innovative products. Founded in Turin in 1966, today it designs and manufactures clamping equipment with high technological content, as well as automatic pallet change systems for vertical lathes and machining centres, die change shuttles for presses.

The solutions conceived by the Italian company find application in almost all sectors: aerospace and automotive, energy and wind power, bearings and transmission units, shipbuilding and oil industry, up to the most standard general mechanical machining.

ROTOMORS mainly operates in the aerospace and automotive fields.

Products

Aircraft Systems / Structure / Metal components / Propulsion Systems / Rotating Components / Stationary Components

Space Systems / Platform / Propulsion and RCS / Entry Descent and Landing / Power

Processes

Manufacturing / Machining / Milling / Turning / Grinding

Miscellaneous / MRO

Other key sectors

Automotive, Mechatronics